The Dynamic Growth of Diecasting in Malaysia

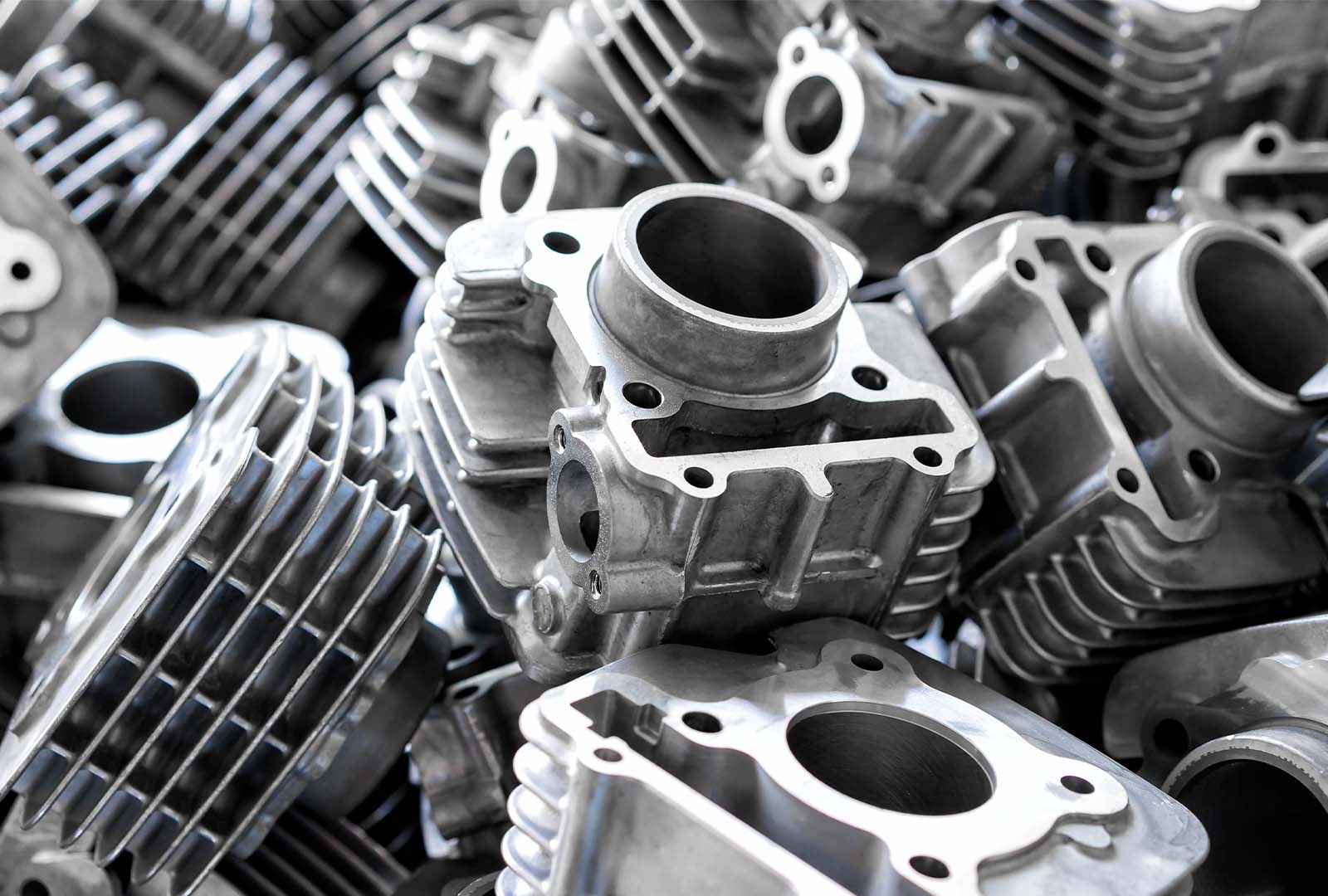

Diecasting has become an essential sector in Malaysia which is driving substantial advances in the field of manufacturing. Diecasting, which entails the injection of molten metal into molds to make intricate and precise shapes, is crucial to create high-end parts used in a variety of sectors, such as electronics, automobiles and consumer goods. The rapid growth of diecasting in Malaysia is an indication of the nation’s industrial strength and its strategic efforts that aim to boost manufacturing quality. In the meantime, as Malaysia is continuing to consolidate its status as a world-class manufacturing center and a major player in the industry of diecasting, it has a major role to play in the country’s economic development as well as technological development.

Diecasting’s growth business in Malaysia has been driven by Malaysia’s focus on diversification of the economy and industrialization. The government’s policies and incentives have led to significant investment in the manufacturing industry, creating the environment that encourages technological innovation as well as industrial growth. In addition, the establishment of special industrial zones and the creation of infrastructure has further enhanced Malaysia’s diecasting capabilities. These efforts have not just drawn in multinational companies, but have additionally enabled local businesses to grow their business and improve their technical knowledge. This has meant that Malaysia has grown into a leading market player on the international diecasting industry, offering quality components to many industries around the world.

The technological advancements have been an important factor in the advancement of diecasting processes in Malaysia. Modern technology like computer-aided design (CAD) and computer-aided manufacturing (CAM) as well as automation have significantly increased the accuracy effectiveness, efficiency, and reliability of diecasting procedures. The latest technologies allow producers to make complex and highly-tolerant components with very little defects and in compliance with the rigorous quality standards set in industries such as aerospace and automotive. Additionally, the use with real-time monitoring systems as well as data analytics have improved the process controls, which allows companies to improve production processes and minimize the amount of waste. A constant expenditure on the research and development (R&D) assures that Malaysian diecasting industry stays on the cutting edge in technological advancement.

It is important to note that the Malaysian diecasting industry also stresses sustainable practices as well as environmental accountability. Since awareness about environmental concerns expands, there is an growing demand for more environmentally sustainable manufacturing methods. Malaysian diecasters are adopting environmentally friendly methods and products to reduce their impact on the environment. It includes using recycled metals, efficient methods of production, and methods to reduce waste. Furthermore, compliance with the international standards for environmental protection and accreditations demonstrates the industry’s determination to sustain. Through embracing environmentally friendly manufacturing practices that the Malaysian diecasting industry not just is in compliance with global standards for environmental sustainability, however it also increases its ability to compete within the international marketplace.

Development of human capital is another important factor that contributes to the growth of Copper plating Malaysia. An experienced and well-educated workforce is vital to maintain high levels of quality and innovative. Malaysian education institutions as well as vocational training centres work with industry partners to deliver specialized training courses to equip employees with the required technical abilities as well as knowledge. Regular professional development efforts assure that the workforce is current with the latest developments regarding diecasting techniques and methods. The emphasis placed on developing human capital fosters the culture of excellence as well as creativity, which drives the industry’s development and efficiency.

Diecasting as a business in Malaysia is an active and fast-growing sector that is a major contributor to the nation’s economy and industrial environment. Government initiatives that are strategic as well as technological innovations, sustainability initiatives, as well as human capital growth are all helping propel the sector into new heights. As Malaysia is continuing to establish itself as a major manufacturing center in the world as it expands, the industry of diecasting will play an ever-increasing part in assisting a variety of high-precision and high-tech industries. A constant determination to innovate, quality and sustainability guarantees it is that Malaysian diecasting industry is strong and competitive in world’s challenges and potential. By focusing on continuous advancement and collaboration with strategic partners The industry has the potential to continue its steady expansion and growth over the next few years.